About us

ModuleUA is one of the largest companies in Ukraine for the production of thin hot dipped galvanized flat steel in coils, prepainted steel in coils, and formed steel sheets.

The company’s capacities allow us to provide the Ukrainian market and our foreign customers with high-quality products with the required volumes.

1

Located in Kamianets-Podilskyi,

the company’s facilities are in a region with an extensive railway and road network, which allows prompt delivery of products to customers throughout the country. And a proximity to the border provides additional advantages for exports.

2

The company ranks second in Ukraine in terms of capacity

for the production of galvanized flat products (200,000 tons per year).

3

The production facilities are equipped with modern equipment,

and our raw materials meet international quality standards.

4

The company's staff consists of qualified employees and young specialists.

This combination of experience and a modern approach allows us to save and transfer knowledge and quickly introduce neoteric technologies into our production.

Production

profile

The Company has modern highly productive domestic and imported equipment.

Push-Pull Type Pickling Line

- “DeltaBrands, Inc.” (USA) push-pull type pickling line with a production capacity of 200 000 tons per year, working with the application of hydrochloric acid.

- Raw coil specification: weight – up to 25 tons, width – up to 1300 mm (for hot-rolled coils with untrimmed edge) and up to 1250 mm (for hot-rolled coils with trimmed edge), strip thickness – 1,5 – 3,0 mm (hot-rolled coils)

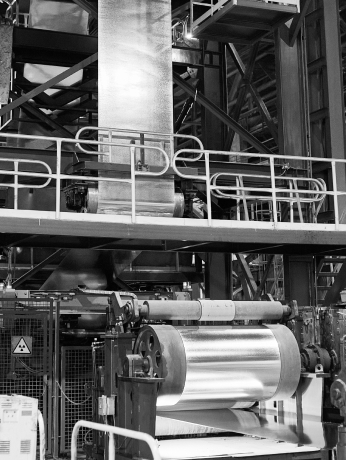

Reversing Cold Rolling Mill

- The mill’s design capacity (4-roll, single-stand, reversible; installed in 2008) is 200 000 tons of cold-rolled strip per year for the Continuous Hot Dip Galvanizing Line.

- Minimum strip thickness – 0,3 mm

- Maximum strip width – 1250 mm

- Maximum rolling speed – 10 m/sec

- Coil weights – up to 25 tons (new lifting crane)

Continuous Hot Dip Galvanizing Line

- Galvanized line designed by “Delta Brands, Inc.” USA with a capacity of 200 000 tons per year

- Raw coil weight – up to 25 tons, galvanized coils – up to 10 tons

- Thickness/width of the strip – 0,32-1,2 mm/up to 1250 mm

- Zinc coating weight – 80-200 g/m² at both sides

Continuous coil coating line designed by FATA, Italy

- The line for applying a polymer coating to galvanized rolled metal designed by “Fata-Hunter” (Italy) with a capacity of 80 000 tons per year

- Polymer coating is applied with painting rolls

- Thickness/width of the strip to be processed is 0,3-1,5 mm/900-1600 mm

- Thickness of the coating on the top side is 27 microns

- Weight of the coil is up to 10 tons

Lines for forming galvanized and prepainted steel sheet

- Equipped with: forming unit СКМЗ with production capacity 45 000 tons per year, and profiling units designed by “Finprofil” (2002) with production capacity 15 000 tons per year

- Raw materials: galvanized steel in coils 0,3-1,2 mm х 1000-1250 mm; prepainted galvanized steel in coils 0,4-0,8 mm х 1000-1250 mm

- Ready product: corrugated prepainted and galvanized steel sheets С15, С18, Н26R, НС45, Н57

Company’s Products

- Galvanized steel in coils;

- Prepainted galvanized steel in coils – paint colors: standard RAL catalog or special customer demands

- Corrugated prepainted and galvanized steel sheets ЛП С15, ЛП Н26R, ЛП НС45, С18, Н57, Н75.

™ ModuleUA products are characterized by durability, resistance to mechanical damage, high fire resistance and water-repellent properties.